HVAC Design & Engineering Services

Precision-Engineered Comfort, Efficiency, and Reliability

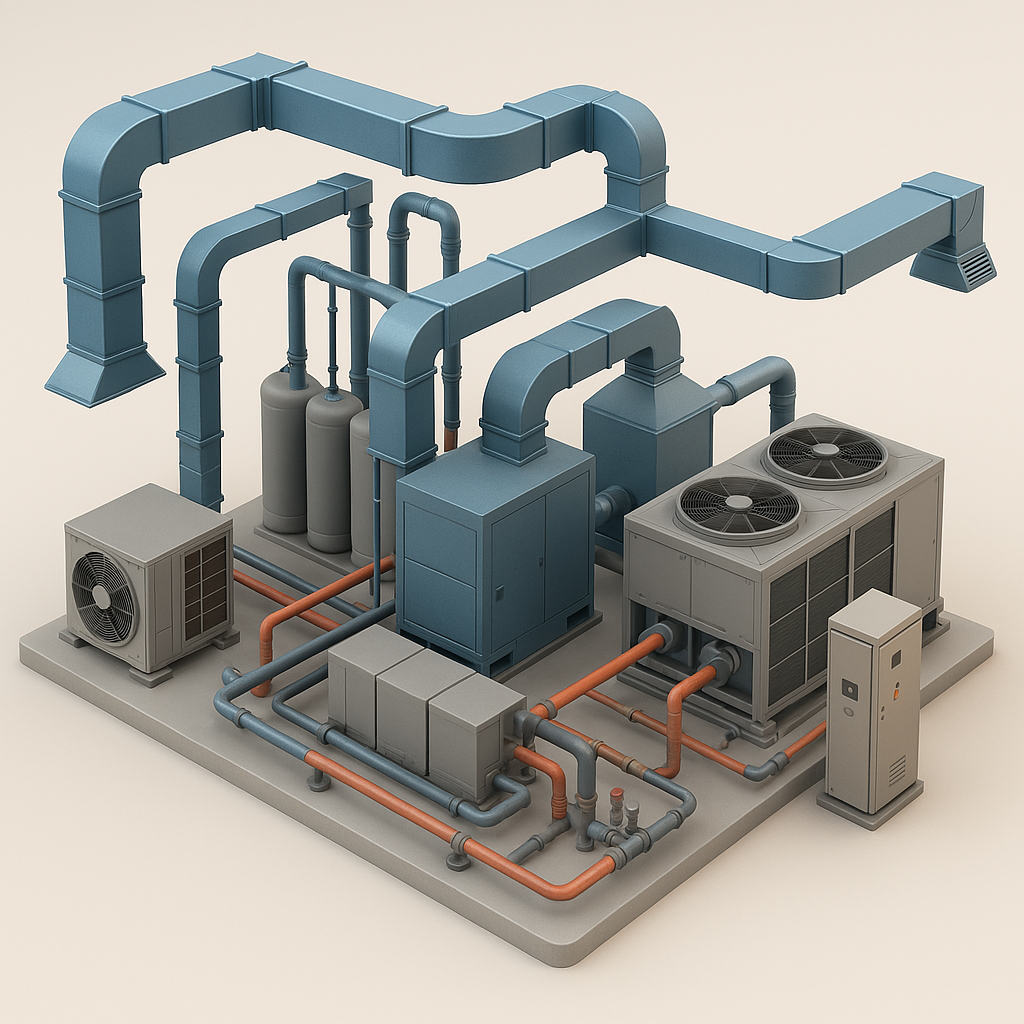

At MECHGLOBAL, we specialize in delivering custom HVAC design and engineering solutions tailored to meet the unique needs of each project. From small commercial buildings to large industrial facilities, our expert engineers integrate advanced technology, sustainability, and best practices to ensure optimal indoor climate control and energy efficiency.

Our HVAC Design & Engineering Capabilities

- System Design & Layout

We provide detailed HVAC system design, including ductwork layout, equipment sizing, and airflow distribution. Our designs are based on load calculations, occupancy needs, and architectural coordination. - Load Calculation & Energy Modeling

Using industry-standard tools like Manual J, Manual D, and energy modeling software (e.g., Trane TRACE, Carrier HAP), we ensure your HVAC system is right-sized for maximum performance and efficiency. - Equipment Selection & Specification

We evaluate performance, energy use, and cost-efficiency to select the best HVAC equipment for your needs—whether it’s VRF/VRV, split systems, chillers, or packaged rooftop units. - Controls & Automation Integration

Our team designs intelligent control systems that integrate with Building Management Systems (BMS), allowing real-time monitoring, zoning, and energy optimization. - Compliance & Documentation

We ensure all designs comply with local codes (ASHRAE, IECC, LEED, etc.), and we provide full documentation including construction drawings, equipment schedules, and specification sheets.

Industries We Serve

- COMMERCIAL OFFICES

- INDUSTRIAL FACILITIES

- SKID/CONTAINERISED PACKAGES

- MULTI-FAMILY RESIDENTIAL

- EDUCATIONAL INSTITUTIONS

- HEALTHCARE & LABS

- HOSPITALITY & RETAIL

Our comprehensive range of HVAC products includes equipment such as:

Air Handling Units (AHUs)

Explore our comprehensive range of high-performance Air Handling Units designed for energy efficiency, optimal air quality, and long-term reliability. Whether your project requires a compact unit for a small space or a fully customized solution for a large facility, we’ve got you covered.

🔹 1. Compact AHUs

Ideal for small commercial spaces, offices, or apartments where space is limited.

Features: Plug-and-play design, energy-efficient EC fans, integrated controls

Airflow Range: 500 – 3,000 CFM

🔹 2. Modular AHUs

Flexible and scalable solutions for medium to large commercial and institutional buildings.

Features: Customizable sections (cooling, heating, filtration), indoor/outdoor installation, energy recovery options

Airflow Range: 3,000 – 50,000+ CFM

🔹 3. Hygienic AHUs

Designed for cleanrooms, hospitals, and pharmaceutical applications with strict hygiene standards.

Features: Stainless steel interiors, smooth surfaces, HEPA filtration, easy-to-clean design

Compliance: ISO 14644, GMP standards

🔹 4. Energy Recovery AHUs

Maximize energy savings by recovering heat or coolth from exhaust air.

Features: Heat recovery wheels or plate exchangers, low energy consumption, smart sensors

Efficiency: Up to 85% heat recovery

🔹 5. Rooftop Packaged AHUs

All-in-one rooftop solutions for commercial and retail environments.

Features: Integrated heating/cooling, compact footprint, weather-resistant casing

Application: Retail chains, malls, warehouses

🔹 6. Custom AHUs

Engineered-to-order units tailored to your specific building or industrial process needs.

Features: Flexible configurations, advanced control systems, large-scale performance

Airflow Range: Fully customizable

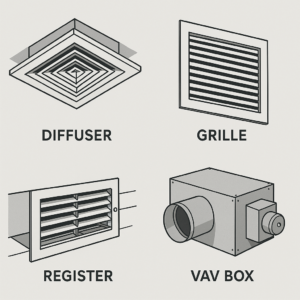

Air Terminal Devices

Air terminal devices”, often used in HVAC (Heating, Ventilation, and Air Conditioning) systems. These are components that regulate and direct airflow within a building. Here’s a quick overview:

🔧 Types of Air Terminal Devices

Diffusers

Spread the air evenly in multiple directions.

Common in ceilings.

Types: square, round, linear slot diffusers.

Grilles

Allow air to return to the HVAC system or supply air in a more focused way.

No moving parts.

Types: return air grilles, supply grilles.

Registers

Like grilles, but with adjustable dampers to control airflow.

Found in floors, walls, or ceilings.

- VAV (Variable Air Volume) Boxes

Control the amount of air delivered to a space.

Often used in commercial buildings to maintain comfort and efficiency.

Displacement Ventilation Units

Supply air at low velocities near the floor.

Good for large spaces and energy efficiency.

Induction Units

Mix primary air from the HVAC system with room air.

Often used in chilled beam systems.

💡 Functions

Distribute conditioned air efficiently.

Ensure thermal comfort.

Reduce drafts and noise.

Maintain proper air mixing and ventilation.

Want help choosing the right one for a space.

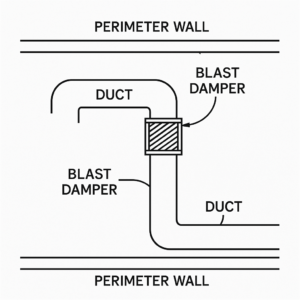

Blast Dampers

HVAC blast dampers are specialized safety components used in heating, ventilation, and air conditioning (HVAC) systems to protect buildings and personnel from explosions or high-pressure shockwaves. They’re commonly found in facilities where there’s a risk of explosion, such as chemical plants, military installations, laboratories, and oil & gas facilities.

Key Functions of Blast Dampers:

Explosion Protection: Designed to close quickly in response to a blast wave, preventing the shockwave and harmful gases from entering HVAC ducts and spreading through the building.

Maintains Structural Integrity: Helps minimize damage to the HVAC system and the structure overall by absorbing or redirecting blast forces.

Automatic Operation: Typically operates without external power—mechanically or pneumatically triggered by overpressure.

Main Types:

Pressure-activated dampers: Close when pressure exceeds a certain threshold.

Spring-loaded dampers: Use a spring mechanism to shut in response to sudden pressure increases.

Manual reset: After activation, some dampers must be manually reopened for system reactivation.

Specifications to Consider:

Blast pressure rating (e.g., rated for overpressures of 1 psi to 12 psi or more).

Airflow performance: Should allow normal ventilation without significant pressure drop during regular operation.

Material: Usually made of heavy-duty steel or stainless steel for durability.

Applications:

Petrochemical facilities

Military and defense buildings

Data centers with high-value equipment

Laboratories dealing with volatile substances

Underground bunkers or shelters

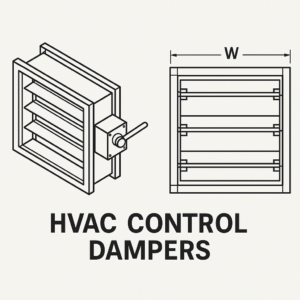

Control Dampers

Types of HVAC Control Dampers:

Types of HVAC Control Dampers:

Volume Control Dampers (VCD):

Used to control airflow volume.

Can be manual or motorized (actuated).

Backdraft Dampers:

Allow airflow in one direction only.

Prevent reverse airflow.

Fire Dampers:

Close automatically when a fire is detected to prevent the spread of flames and smoke.

Smoke Dampers:

Prevent smoke from spreading through the ductwork.

Combination Fire/Smoke Dampers:

Provide both fire and smoke protection.

Zone Dampers:

Used in zoning systems to control air distribution to different areas.

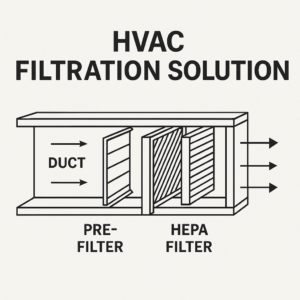

Filtration Solutions

Types of HVAC Filters:

Types of HVAC Filters:

Fiberglass Filters (Panel Filters)

Low-cost, disposable.

Basic protection; mainly traps large dust and debris.

MERV Rating: 1–4

Pleated Filters

Made from polyester or cotton folds.

Better surface area = better filtration.

MERV Rating: 5–13

Electrostatic Filters

Use static electricity to attract particles.

Available in washable or disposable types.

MERV Rating: 5–10

HEPA Filters (High-Efficiency Particulate Air)

Capture 99.97% of particles ≥0.3 microns.

Used in cleanrooms, hospitals, or sensitive environments.

MERV Rating: 17–20

Activated Carbon Filters

Designed to remove odors and VOCs (volatile organic compounds).

Often used in combination with particulate filters.

UV-C Light Systems

Installed in ducts or near coils to kill mold, bacteria, and viruses.

Acts as a disinfection aid, not a particulate filter.

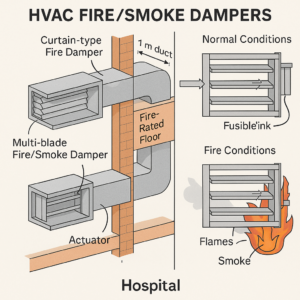

Fire Dampers

Fire dampers are critical safety components in HVAC (Heating, Ventilation, and Air Conditioning) systems. They help prevent the spread of fire and smoke through ductwork during a fire event. Here’s a quick overview:

Fire dampers are critical safety components in HVAC (Heating, Ventilation, and Air Conditioning) systems. They help prevent the spread of fire and smoke through ductwork during a fire event. Here’s a quick overview:

🔥 What Are Fire Dampers?

Fire dampers are passive fire protection devices installed in HVAC ducts. When heat from a fire causes the air temperature in the duct to rise to a certain level (usually around 165°F or 74°C), the damper closes automatically, usually by means of a fusible link or thermal element.

🛠️ Types of Fire Dampers

Curtain-Type Fire Dampers:

Most common type.

Have a folded curtain blade held open by a fusible link.

When triggered, the blades drop down and block the duct.

Multi-Blade Dampers:

Multiple blades pivot to shut the duct.

Better suited for larger ducts or ducts with airflow that makes curtain-type ineffective.

Combination Fire/Smoke Dampers:

Provide both fire and smoke protection.

Include an actuator and are linked to a fire alarm system for smoke detection.

🔍 Where Are They Installed?

At the point where ductwork penetrates a fire-rated wall or floor.

In vertical shafts and horizontal ductwork passing through fire-resistance-rated assemblies.

⚙️ How Do They Work?

Normal Conditions: Damper is open to allow airflow.

Fire Conditions: Heat melts the fusible link or activates a thermal sensor.

Result: The damper closes, preventing fire/smoke from traveling through the ductwork.

🧪 Maintenance Requirements

Must be inspected and tested:

After installation

Annually for most systems

Every 4 years for hospitals (per NFPA 80/105 standards)

Should be kept clean and unobstructed.

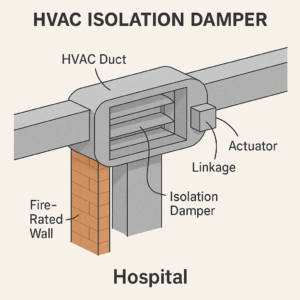

Isolation Dampers

An HVAC isolation damper is a type of damper used to control or completely shut off airflow in a specific section of ductwork. It’s commonly used in large buildings like hospitals, labs, or commercial facilities to isolate parts of the system for maintenance, energy efficiency, or emergency situations.

An HVAC isolation damper is a type of damper used to control or completely shut off airflow in a specific section of ductwork. It’s commonly used in large buildings like hospitals, labs, or commercial facilities to isolate parts of the system for maintenance, energy efficiency, or emergency situations.

🔧 What It Does

Allows certain zones or rooms to be shut off from air circulation

Can be used for contaminant containment, like in infection control rooms

Helpful during maintenance or repairs without shutting down the entire system

🛠️ Types of Isolation Dampers

Manual Dampers

Operated by a hand lever or screw

Used when frequent changes aren’t needed

Motorized (Actuated) Dampers

Controlled by a Building Management System (BMS)

Can be programmed for schedules or emergency shut-off

Low-Leakage Dampers

Designed for systems that require tight shut-off (like clean rooms or operating theatres)

🧩 Where You’ll See Them in Hospitals

Operating rooms

Isolation rooms

ICUs

Pharmacies or clean rooms

Emergency air shut-offs

📏 Key Specs to Consider

Duct size (you mentioned 1m ducts before)

Leakage class (Class 1 is the tightest per AMCA)

Blade type (airfoil blades reduce pressure loss)

Actuator type (spring-return for failsafe shut-off)

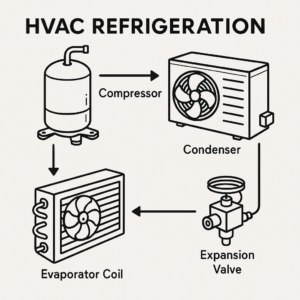

Refrigeration

HVAC Refrigeration refers to the cooling cycle used in air conditioning and refrigeration systems. It’s a key part of HVAC systems that deals specifically with removing heat from a space to make it cooler.

HVAC Refrigeration refers to the cooling cycle used in air conditioning and refrigeration systems. It’s a key part of HVAC systems that deals specifically with removing heat from a space to make it cooler.

❄️ Core Concept: The Refrigeration Cycle

Most HVAC systems use a vapor-compression refrigeration cycle, which has four main components:

Compressor

Compresses low-pressure refrigerant vapor into high-pressure vapor.

Located outside in most split systems (in the condenser unit).

Condenser Coil

Releases heat to the outside air.

Turns high-pressure vapor into a high-pressure liquid.

Expansion Valve (or Capillary Tube)

Reduces the pressure of the refrigerant.

Prepares it to absorb heat by cooling it down rapidly.

Evaporator Coil

Located inside the air handler or furnace.

Absorbs heat from the indoor air, cooling it down.

Turns refrigerant back into a low-pressure vapor.

🔄 The Refrigeration Cycle in Action

Compressor → High-pressure hot gas

Condenser Coil → Releases heat, refrigerant becomes a liquid

Expansion Valve → Pressure drops, refrigerant cools

Evaporator Coil → Absorbs heat from indoor air, providing cooling

Back to Compressor → Cycle repeats

🧊 Refrigerants

Common refrigerants:

R-410A (widely used, being phased out)

R-32 (lower GWP, more environmentally friendly)

R-134a, R-22 (older systems, mostly phased out due to environmental regulations)

🏥 In Hospitals and Commercial Buildings

Used in chillers, VRF systems, and centralized cooling systems.

Often part of an integrated HVAC & BMS (Building Management System) for energy efficiency and precise temperature control.

Water Removal

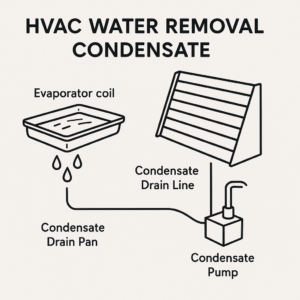

How Condensate Forms

How Condensate Forms

Warm, humid indoor air passes over the cold evaporator coil.

As the coil cools the air, the moisture in the air condenses on the coil — like water droplets on a cold glass.

This water is called condensate.

🛠️ How It’s Removed

HVAC systems include components specifically for draining this water:

Condensate Drain Pan (Drip Pan):

Catches the water dripping off the coil.Condensate Drain Line:

A pipe or tube that carries water from the drain pan to a drain or outside.Condensate Pump (optional):

If gravity can’t move the water (e.g., basement setups), a small pump pushes it out.

⚠️ Common Problems

Clogged Drain Line:

Algae, dirt, or debris can block the pipe, causing water to back up.Overflowing Drain Pan:

Leads to water damage or mold growth.Pump Failure:

Can result in leaks or HVAC shutdown if the system has a float switch.

🧼 Maintenance Tips

Flush the drain line periodically with vinegar or a specialized cleaner.

Make sure the drain pan is clean and rust-free.

Ensure the pump (if present) is working.

Why Choose Us?

✅ Professional Engineers with extensive of HVAC design experience

✅ Energy-Efficient Solutions that reduce operating costs

✅ BIM & CAD Integration for seamless project coordination

✅ Fast Turnaround without compromising on quality

✅Design-to-Construction Support: From concept to commissioning, we stay involved every step of the way.

Let’s Build Your Climate Solution

Whether you’re designing a new building or upgrading an existing system, our HVAC engineers are here to guide your project from concept to completion. Contact us today to schedule a consultation or request a proposal.

📞 Get in Touch

Ready to discuss your project?

Contact us for a free consultation or project quote.

📧 Email: info@mechglobal.co.uk

📞 Phone: (+44) 1612311274

🌐 Website: www.mechglobal.co.uk